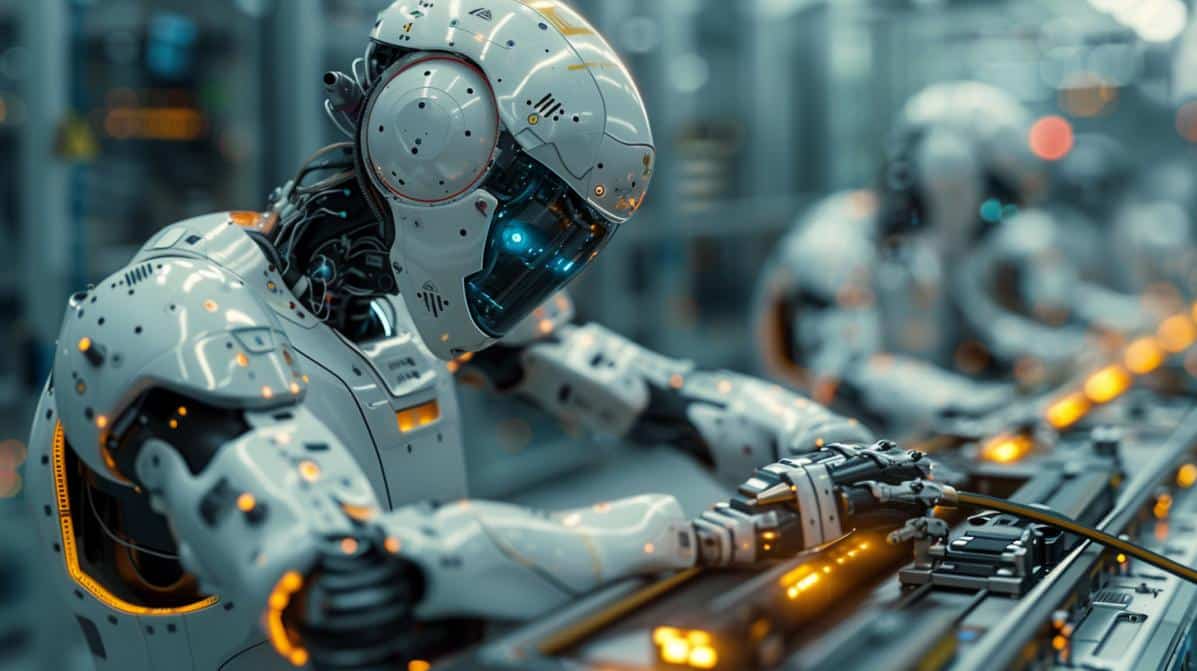

Imagine a world where routine tasks are performed with unparalleled precision and efficiency, a scenario where humans and machines collaborate to achieve the unimaginable. At the heart of this reality is robotics. In “[Robotics in Everyday Life: Change in Industries]”, let us delve into the waves of transformation that robots are causing in a silent but powerful way in industries. From mechanical arms that dance in symmetry on production lines to digital assistants that facilitate our existence, digital transformation has become the stage where robotics shines, reshaping not only the way we work, but also the essence of industries themselves. Come and discover how this technological alchemy is shaping our present and shaping our future.

How are robotics integrated into daily activities?

Robots are present in our daily lives, fundamentally changing production methods, service delivery and routine tasks. In manufacturing, robotics has increased precision and efficiency, enhancing productivity and minimizing human errors. In the automotive industry, the use of robots for welding, painting and assembly is intense, ensuring quality and safety, and promoting faster production rates. In healthcare, robotic assistants in surgeries perform complex procedures, shortening recovery times.

In the agricultural sector, the application of robots for planting, harvesting and monitoring has improved agricultural practices and increased crop productivity through tireless operations and data collection. In logistics and storage, robots optimize processes by classifying, packaging and transporting goods, managing larger volumes with greater precision and lower labor costs. In customer service, chatbots and virtual assistants are integrated, which manage large volumes of queries continuously without proportional growth in human resources.

While some jobs may be displaced, new opportunities in robot management, programming and maintenance are also expected to be created. The costs of investing in robotics are high, but the long-term benefits, such as continuous operation without the need for breaks or sick days, can offset these expenses.

Limitations of robotics include required maintenance, risk of technical failures, and challenges in updating systems that can disrupt workflows. Ethical concerns emerge, including the potential for AI bias and the effects of robots on human interactions. In summary, robotics plays a transformative role in diverse sectors, enhancing varied aspects of industrial operations while debating economic concerns, investment considerations, and ethical discussions.

What industries have been transformed by robotics?

Robotics has fundamentally altered manufacturing, increasing precision and efficiency, reducing human error and improving productivity. In the automotive industry, it is vital for welding, painting and assembly processes, ensuring safety and quality with superior production speeds. In healthcare, it assists in surgeries, with robots that perform complex procedures, reducing recovery times. In agriculture, they are employed in planting, harvesting and monitoring, improving agricultural production and increasing crop yields through uninterrupted operations and data collection. In logistics, they optimize the selection, packaging and transport of goods, handling larger volumes with greater precision and reduced labor costs. In customer service, chatbots and virtual assistants handle a large volume of queries 24 hours a day without the need for a proportional increase in human resources. While robotics may displace some jobs, it is also expected to create new opportunities in robot management, programming and maintenance. Initial investments in robotics are high, but long-term benefits, such as continuous operation without the need for breaks or sick days, can offset these expenses. Limitations of robotics include the need for maintenance, risk of technical failures, and challenges in updating systems that can disrupt workflows. Ethical concerns arise, including the potential for AI bias and the effects of robots on human interactions. In summary, robotics plays a transformative role across multiple sectors, improving various aspects of industry operations and addressing economic concerns, investment considerations, and ethical debates.

What are the impacts of robotics on operational efficiency?

Robotics has increased operational efficiency in industries to previously unattainable levels. The impact of robotics on production translates into a measurable increase in productivity, as robots work faster and with greater precision than humans. Thanks to the introduction of robots, human errors in operations have been significantly reduced, which consequently improves the quality of the final product and optimizes the use of materials and resources.

In automotive assembly lines, for example, robots perform welding, painting and assembly tasks with a precision and speed that would challenge human ability, ensuring not only faster production, but also product safety and consistency. In operating rooms, robotic assistance enables complex procedures with greater precision and shorter recovery times for patients. In the agricultural sector, robots help plant and harvest, as well as monitor crop conditions, contributing to more efficient agricultural practices and increased crop production through tireless operation and data collection.

In logistics and warehousing, robots speed up processes when sorting, packaging and transporting goods, managing higher volumes with superior precision and lower labor costs. In customer service, the integration of chatbots and virtual assistants makes it possible to manage a large volume of queries 24 hours a day without requiring a proportional increase in the number of human employees.

In addition to influencing efficiency, robotics creates employment opportunities in areas such as robot management, programming and maintenance, showing that its impact extends far beyond the factory floor.

Therefore, it is undeniable that robotics has transformed operational efficiency in many industries, presenting both challenges and opportunities for the future of work and production.

What are the emerging trends in industrial robotics?

Emerging trends in industrial robotics mainly encompass technological innovations in robotics and the increasing integration of artificial intelligence. These innovations are not only reshaping production processes to be more efficient and precise, but they are also creating new employment opportunities. In the manufacturing sector, the presence of robots is already a game changer in the way products are built and assembled. Artificial intelligence, on the other hand, is becoming more sophisticated and capable of performing complex tasks that were previously exclusive to the human touch, such as identifying patterns and making immediate decisions.

In the automotive industry, robotics is fundamental in areas such as welding, painting and assembly, ensuring not only quality and safety, but also agility in manufacturing processes. In agriculture, robots are essential for planting, harvesting and monitoring, improving agricultural practices. From a healthcare perspective, robots are a major advance in surgical care, enabling complex procedures that reduce patients' recovery time.

Storage and logistics areas also benefit from robotic efficiency, where robots are used to order, pack and transport products, increasing precision and reducing labor costs. In customer service, the integration of chatbots and virtual assistants manages large volumes of queries 24 hours a day, without the proportional need for human resources. Although robotics may displace some jobs, it is also expected to create new opportunities in the management and maintenance of robots.

Certainly, robotics involves high initial investment costs, however, the benefit of continuous operation without breaks or sick days offers long-term financial balance. Challenges exist, from necessary maintenance, risk of technical failures, to ethical issues such as the potential bias of AI and the effects of robots on human interactions. In short, robotics is playing a transformative role across multiple industries, enhancing various aspects of industrial operations while also addressing economic concerns, investment considerations, and ethical debates.

What challenges and limitations do robotics currently face?

Modern robotics, although already deeply integrated into several industries, faces significant challenges in ensuring workplace safety and maintaining high quality standards. These two issues are critical when considering the increasing insertion of robots in environments where there is direct human interaction or when their functions require absolute precision.

In the context of occupational safety, the main challenge is to develop systems that can predict and react to unexpected situations, protecting human operators from accidents. Likewise, quality standards require robots to work consistently and without failure, demanding robust and reliable technology. These are complex issues because they range from mechanics and electronics to artificial intelligence and machine learning systems.

On the other hand, companies are moving forward in overcoming these limitations with investments in R&D and the adoption of more advanced AI systems that improve the efficiency of robots and their ability to operate safely among human workers and in critical quality processes. .

Strategies to overcome these barriers include improving robot programming, increasing the use of high-precision sensors, and developing new collaboration frameworks between machines and humans.

Faced with the aforementioned challenges, the tendency is for robotics to continue evolving, increasingly integrated into our daily lives, driving advances that will further revolutionize industries and the job market.

What ethical considerations arise with the expansion of robotics?

The social impacts of robotics range from changing human interactions to issues of AI bias. In the field of required skills, robotics is causing significant change, requiring modern workers to have specialized knowledge in managing, programming and maintaining robots. The social implications of this growing use focus on changes in employment dynamics and workers' competence. Professionals need to adapt, developing advanced technical skills to keep up with the demand for specialists capable of operating and maintaining complex robotic systems.

Robotics in Everyday Life: Change in industries

Robotics has significantly transformed industries, promoting a true revolution in day-to-day operations. In manufacturing sectors, the introduction of automated systems and robots has resulted in a notable increase in precision and efficiency. The automotive industry is one of the emblematic examples of this change, making extensive use of robots for welding, painting and assembly. This mechanization makes it possible to maintain the quality and safety of vehicles, while boosting production speed.

In healthcare, robotics plays a crucial role, offering assistance in surgeries and, in some cases, performing complex procedures that reduce patients' recovery time. In agriculture, the adoption of robots for planting, harvesting and monitoring improves agricultural practices and results in an increase in crop production.

In the warehousing and logistics sector, robots are used to optimize processes such as sorting, packaging and transporting goods, handling larger volumes more precisely and reducing labor costs. Customer service services have also been impacted by the integration of chatbots and virtual assistants, which manage large volumes of queries continuously without proportionally increasing the human resources involved.

While there is concern about job replacement, robotics also creates new opportunities in areas such as robot management, programming and maintenance. The initial investment costs are high, but the long-term benefits, such as continuous operation without the need for breaks or sick days, tend to offset these expenses.

Despite this, there are limitations such as the need for maintenance, risks of technical failures, and challenges in updating systems that can interrupt the workflow. Additionally, ethical concerns are emerging, including the potential for AI bias and the effects of robots on human interactions. In summary, robotics has assumed a transformative role in diverse sectors, excelling in improving industrial operations and also addressing economic concerns, investment considerations and ethical debates.

Throughout this article, we explore the fascinating integration of robotics into everyday spheres, bringing to light tangible examples of how these technologies live with us. We see digital transformation driving the adoption of robots in different industries, reinventing processes and creating new employment opportunities. We discerned the positive impact on operational efficiency, with increased productivity and reduced human errors. Furthermore, we identify innovations and trends that outline the future of industrial automation, and reflect on the ethical and technical challenges that emerge in parallel.

In conclusion, it is undeniable that robotics is shaping our existence, bringing simultaneous benefits and challenges. As we enter the era of artificial intelligence and advanced automation, we are left to ponder not only how robots can improve our activities, but also how we can evolve harmoniously with these machines that, from day to day, become companions to our lives. journey.

Frequently Asked Questions (FAQ)

Which sectors have been significantly transformed by robotics?

Robotics has notably transformed manufacturing, the automotive industry, healthcare, agriculture, logistics and customer service. It has improved efficiency, accuracy, and end-product quality in these industries, and created new employment opportunities while reducing the potential for human error.

How has robotics increased the operational efficiency of industries?

Robotics has increased operational efficiency by increasing productivity with faster operations and reducing human errors, ensuring quality and safety. This includes welding, painting and assembly tasks in the automotive industry and surgical procedures in the healthcare sector, as well as improving agricultural practices and optimizing logistics and storage processes.

What are the main challenges and limitations facing robotics today?

The main challenges of robotics include ensuring safety in the workplace, maintaining high quality standards and developing systems that respond effectively to unexpected situations. Limitations include the need for ongoing maintenance, risk of technical failures, and the complexity of updating systems, as well as ethical concerns related to AI bias and the effects on human interactions.

What ethical questions are raised by the advancement of robotics?

The advancement of robotics raises ethical questions such as the potential bias of AI and the effects on employment and human interactions. This creates the need for professionals to develop advanced technology skills to manage, program and maintain robotic systems, which changes the dynamics of employment and demands specific skills in the job market.

How are robotics integrated into daily activities and contributing to industrial change?

Robotics are integrated into everyday activities by transforming manufacturing, the automotive industry, medicine, agriculture and the service sector. Its applications have generated operational efficiencies through greater task precision and the ability to operate continuously without human needs for rest or health recovery, which boosts productivity and quality across multiple industries.